You might hear some advocates say things like “Hemp is cannabis!” or “It’s the same plant!” That’s true, they’re varieties of the same plant bred to have different expressions of cannabinoids in compliance with regulations. Although our crop is federal Farm Bill compliant HEMP, you’ll soon find out that the exact same blood, sweat, tears, mind, body, and spirit that goes into medical grade cannabis is what goes into the hemp from Banner Harvest.

Seeds and Clones

Plants get their start two ways, from seeds and from clones. We use both methods of starting plants, but seeing as clones produce a more consistent result, most of our genetics come from mother plants that we snip cuttings from in the early spring to prepare for planting. Once the baby clones become toddlers, they’re ready for the field.

Planting

Installing weed control and irrigation, being mindful of using the resources already available on the land. Each plant is placed in the ground by hand with TLC.

Preparing the field.

Adding irrigation.

Planting by hand with love.

Freshly planted.

Volunteer plants from last season.

Another volunteer hanging by the barn door.

Juvenile Plants

As the plants mature, every step of the process is carefully monitored by our master grower ensuring each plant gets the nutrients and attention they need to produce the best end product possible.

Battling the Elements

It takes a skillful grower who is connected to the plants always ensuring they get the protection they need to battle the unpredictable weather we have here in Central Illinois. From droughts to floods to tornadoes, we’ve seen it all.

The Best of the Best

Premium Smokable Flower is always hand selected at the prime flowering stage of the plant. We start by removing the fan leaves (the leaves that catch water) and inspecting each bud for quality. The best buds are cut and hung in a temperature controlled environment until they’re dry enough to trim. They are then re-inspected as they’re hand trimmed and packaged for sale.

Mature Plants ready to harvest.

Fanned Colas.

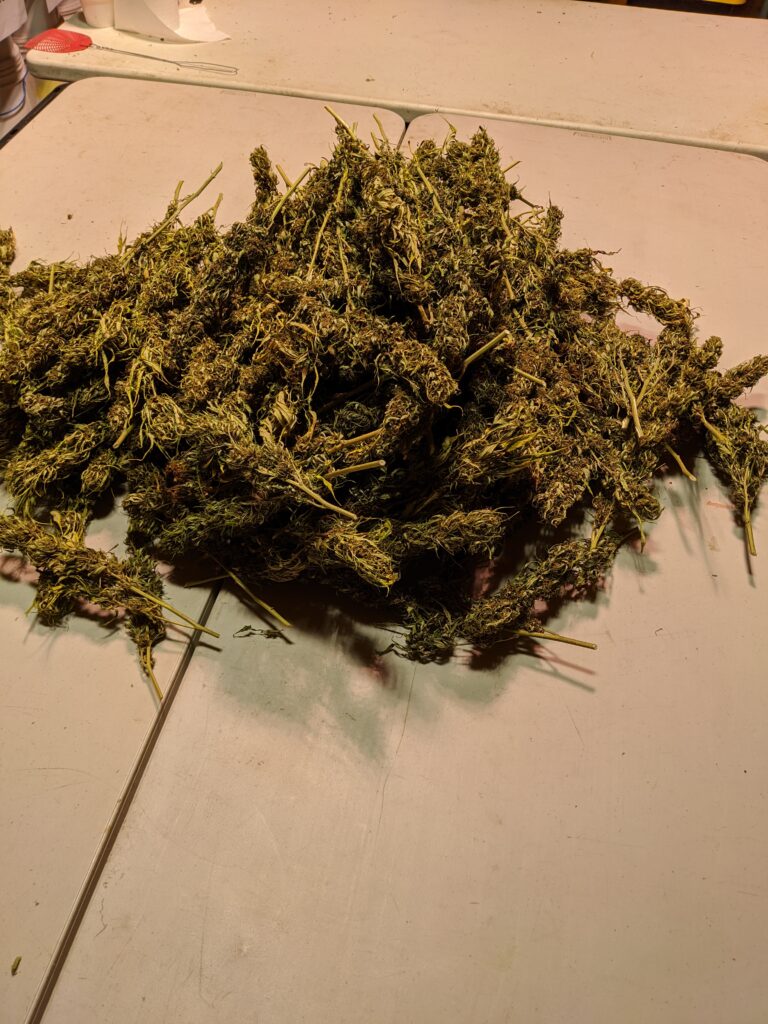

Ready for trimming.

Snip Snip Snip

Premium Quality

The Rest of the Rest

The rest of the plant is culled over again in case any premium buds were missed, and then shucked into super sacks becoming biomass. The biomass is sorted to removed any large stems or leaves, then prepared for processing also known as extraction producing distillate and isolate

To make CBD oil, one must start with CBD-rich plant material. There are several ways to extract CBD oil from cannabis. Each method has its pros and cons. Some are safer and more effective than others.

The purpose of an extraction is to make CBD and other beneficial components of the plant (such as terpenes) available in a highly concentrated form. Because cannabinoids are founds in the trichome oil of the plant, separating cannabinoids and terpenes from the plant material will produce a thick, potent oil. The texture and purity of the oil depends largely on the quality of hemp biomass used, the method used to extract it and the quality of the distillation process thereafter.

The extraction can be further broken down to remove all other cannabinoids and terpenes besides CBD. This creates an isolated version of the product safe for consumers avoiding any and all THC.

Full Spectrum Distillate

CBD Isolate

End Product

After it is extracted from the plant and the solvent is removed, the CBD oil may be refined and formulated into a variety of consumable products – edibles, tinctures, gel caps, vape oil cartridges, topicals, beverages, and much much more. The possibilities are truly endless.

Market

For two years we’ve spent our Saturday mornings making our products available at the Peoria Riverfront Farmers Market. More reliable than the US postal service, we bring our smiling faces (behind masks of course) and the full line up of products at farmers market prices. The markets runs from May-September and offers us a chance to connect with the community and other local business.